no big news, but some info regarding the stuff I used on the lifters and the cam surface:

I found a fuel pump block off plate, deep in my parts stash - I am still undecided if I use the mechanical VW pump or an electric one...

Later this week: short block assembly!

Oh - of course I was at the Techno Classica in Essen, the biggest classic cars show on earth - according to the organizers...

All I can say, it is not cheap to go there, the prizes for classic cars are unreal and it is more and more a meeting for the "rich and famous" - unfortunately!

I still found a few parts, but almost all of the VW part dealers are not there any more, strictly Porsche, Mercedes, Ferrari and other high class classics...

Here is what I found:

a new cushion for my car jack, a 38mm socket with 3/4" drive, a new coil and some electric stuff.

about this Blog

After I (more or less) finished my 1966 Volkswagen Fastback the "Volksback", it was time for another challenge, here it is!

Sonntag, 30. März 2014

Dienstag, 25. März 2014

... more assembly pics

Here is the marking on the Schleicher cam:

RO248.7 = which equals 296°; 9 mm lift

set up of axial play measurement:

current reading is 0,12mm - but it wasn't torqued to the max, so I expect ~0,1 axial play

another -very easy- job was to add a missing bolt for the oil strainer plate:

(of course loctite'd)

result:

In the meantime I test-fitted the housing and internals several times, the next step is to finally bolt the halfs together, using the correct sealant. Porsche recommends Loctite 574, so I will use this, too. If it is good enough for a Porsche it should be just right for my VW as well ;-)

RO248.7 = which equals 296°; 9 mm lift

set up of axial play measurement:

current reading is 0,12mm - but it wasn't torqued to the max, so I expect ~0,1 axial play

another -very easy- job was to add a missing bolt for the oil strainer plate:

(of course loctite'd)

result:

In the meantime I test-fitted the housing and internals several times, the next step is to finally bolt the halfs together, using the correct sealant. Porsche recommends Loctite 574, so I will use this, too. If it is good enough for a Porsche it should be just right for my VW as well ;-)

Samstag, 22. März 2014

engine assembly, continued

Here are a few more goodies:

chromoly cylinder studs, a good quality engine gasket set and the CSP oil pressure valve screws with a nice allen head instead of the mega slot...

the story so far:

chromoly cylinder studs, a good quality engine gasket set and the CSP oil pressure valve screws with a nice allen head instead of the mega slot...

the story so far:

Donnerstag, 20. März 2014

Engine assembly, first steps

This week I started with the assembly process of my 1776 ccm engine...

the con rods, equipped with new bearings:

the balanced crankshaft:

the flywheel, resurfaced and lighter than stock:

first check: main bearings and crank, note the markings on the bearings to allow easier assembly

I chose to use a closed spacer ring, even though this motor will not see excessive rpm's:

new followers - always use new followers with a new cam!

the new Schleicher camshaft 286° - which is the correct duration for this (single carburator) engine

cam bearings installed

cam installed, important check: Is there enough clearance between the cam and the follower?

assembly of gears onto the crankshaft:

the gears and spacer have to be heated to allow them to be installed, it is a press fit

As the distributor drive has to be installed early as well, I modified a 009 "copy" to contactless

step 1: remove points and condenser

step 2: assemble the module with the white heat sink paste on the underside

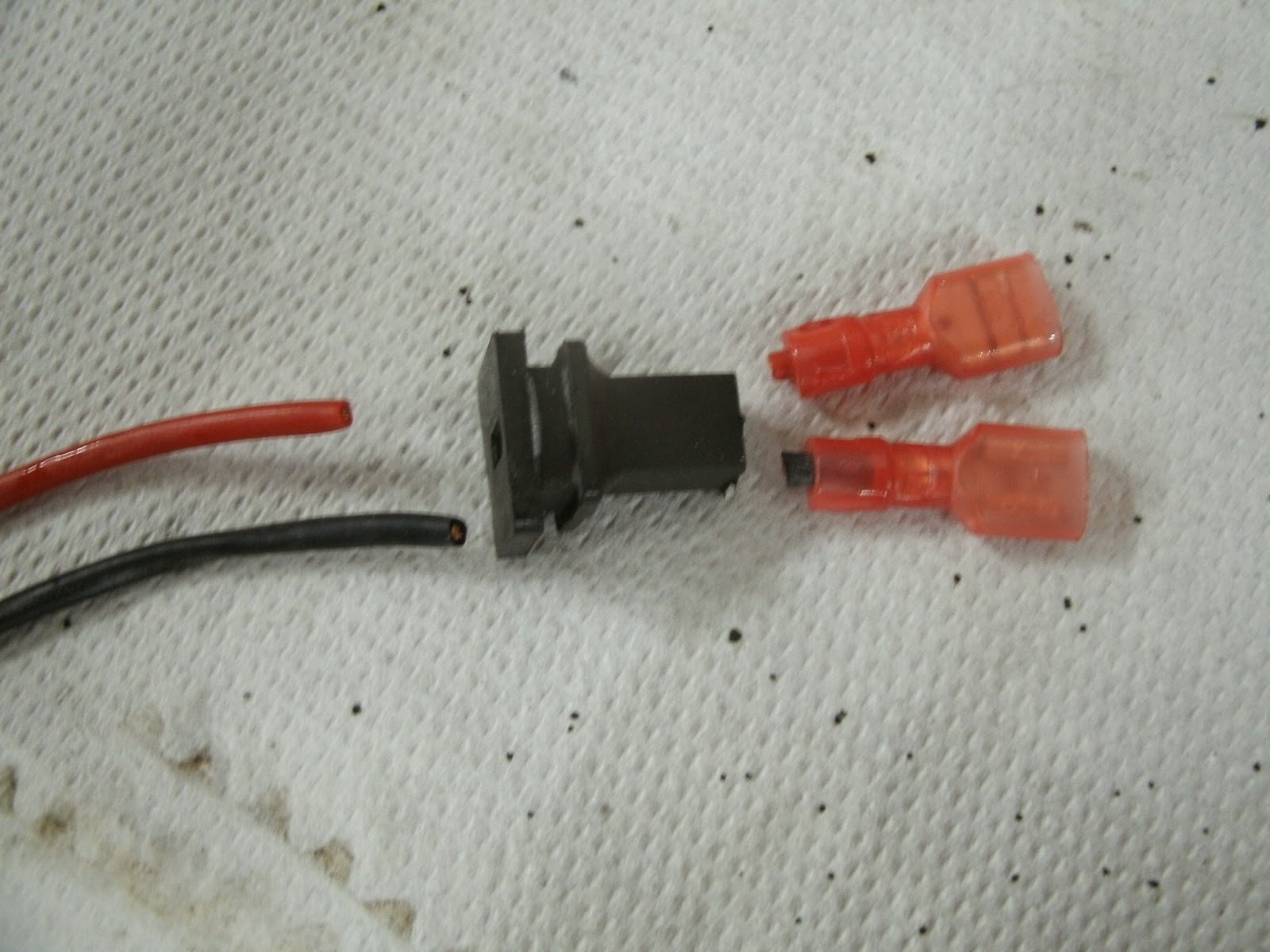

step 3: route the cables to the outside:

step 4: Damn! the cheap chinese copy distributor has the wiring routed different than the Bosch original part! A rectangular grommet will not fit into a round hole!

This was the routing of the copy...

step 5: snip snip - cut off the crimped ends and remove the rubber piece

step 6: use some sleeve to protect the wiring and find a round rubber grommet which fits

route the cable inside the dizzy and secure the tubing with zip ties, so it won't interfere with the moving rotor

looks good!

final step: install the original screw to close the unused thread

(oops - next step: clean your fingers...)

the con rods, equipped with new bearings:

the balanced crankshaft:

the flywheel, resurfaced and lighter than stock:

first check: main bearings and crank, note the markings on the bearings to allow easier assembly

I chose to use a closed spacer ring, even though this motor will not see excessive rpm's:

new followers - always use new followers with a new cam!

the new Schleicher camshaft 286° - which is the correct duration for this (single carburator) engine

cam bearings installed

cam installed, important check: Is there enough clearance between the cam and the follower?

assembly of gears onto the crankshaft:

the gears and spacer have to be heated to allow them to be installed, it is a press fit

As the distributor drive has to be installed early as well, I modified a 009 "copy" to contactless

step 1: remove points and condenser

step 2: assemble the module with the white heat sink paste on the underside

step 3: route the cables to the outside:

step 4: Damn! the cheap chinese copy distributor has the wiring routed different than the Bosch original part! A rectangular grommet will not fit into a round hole!

This was the routing of the copy...

step 5: snip snip - cut off the crimped ends and remove the rubber piece

step 6: use some sleeve to protect the wiring and find a round rubber grommet which fits

route the cable inside the dizzy and secure the tubing with zip ties, so it won't interfere with the moving rotor

looks good!

final step: install the original screw to close the unused thread

(oops - next step: clean your fingers...)

Samstag, 8. März 2014

dome light

A few days ago I cleaned the dome light, which was really dirty...

afterwards: Not perfect, but way better than before...

Freitag, 7. März 2014

body to pan installation

... it is comming together!

Today I bolted the body onto the pan, after I inserted the bakelite heater channel pipe - of course with a new seal!

first of all I used body sealer and rust protection on the edge I fixed a while ago:

the heater channel pipe - with new seal:

afterwards I coated the area with some underseal and attached the pipe:

next topic: body to pan hardware installation:

right side finished (note the perfect, rust free, original heater channels!)

screws and hardware to fix the body onto the front axle beam (steering column connected as well):

lower front screws attached:

left side, finished as well:

Today I bolted the body onto the pan, after I inserted the bakelite heater channel pipe - of course with a new seal!

first of all I used body sealer and rust protection on the edge I fixed a while ago:

the heater channel pipe - with new seal:

afterwards I coated the area with some underseal and attached the pipe:

next topic: body to pan hardware installation:

right side finished (note the perfect, rust free, original heater channels!)

screws and hardware to fix the body onto the front axle beam (steering column connected as well):

lower front screws attached:

left side, finished as well:

Sonntag, 2. März 2014

KAMAZ Dakar 2014 on the road!

Samstag, 1. März 2014

Oldtimermarkt Hamm / classic car swap meet Hamm

Today I visited the classic cars swap meet in Hamm. It was really packed and all parking lots were stuffed before 10:00 am! As usual, also a lot of bike and bicylce dealers were present.The weather was really nice and I got the chance to pick a few parts:

a pair of kick panels (already cleaned in the mean time), an oil presure gauge, a battery clamp, an aux fuse holder with 4 fuses and nice VW sign for my garage wall. I also picked a 3/8" Hazet 11mm socket (not shown) for the con rod screws for my new motor(s)...

a pair of kick panels (already cleaned in the mean time), an oil presure gauge, a battery clamp, an aux fuse holder with 4 fuses and nice VW sign for my garage wall. I also picked a 3/8" Hazet 11mm socket (not shown) for the con rod screws for my new motor(s)...

Abonnieren

Kommentare (Atom)